Testing by Kiwa: quality and reliability ensured

When you bring something new onto the market, you want to eliminate quality and safety risks. After all, your potential customers or clients need to be able to trust your product, component, (raw) material or its application. In other words, they'll have to be confident that it reliably performs the way it is supposed to, compliant with local and international rules and regulations. Kiwa's independent, fully equipped and highly qualified testing labs and services bring that trust.

What Kiwa can do for you

Determine characteristics and prevent disturbance

We test, whether in a laboratory or on-site, to independently determine characteristics and thus approve requirements in terms of safety, quality, performance, reliability and compliance with rules and regulations. Testing also prevents disturbance to daily operations as possible errors and defects can be detected before they do any harm. For example, you need to be certain about the properties of a material within your installation or production facility or about the quality of a weld between pipe segments. Or about the environmental impact your product may have. Kiwa provides you with the knowledge to make the necessary recommendations for high quality installations, maintenance and asset management.

Enlarge the infographic by clicking on it

Testing, measuring and calibrating everything, all over the world

We deliver testing, measuring and calibration services in a wide range of market sectors through over 100 laboratories worldwide, which means there's always a testing facility near you. Our labs are primarily based in Europe and in major manufacturing countries in the Far East. We offer leading expert services in both non-destructive (or non-damaging) and destructive testing. Our services cover a very wide range of testing facilities, equipment, capabilities and know-how. We use advanced methods to reveal hidden defects and employ highly skilled personnel in interpreting the results. So, regardless of the object you want to have tested or its purpose, we know which testing methods suit you best, which local and/or international rules and regulations apply, and we provide you with accurate results.

Research and development

To meet your needs and face future challenges, we do a lot of research in close cooperation with you, our customers. These cooperative efforts allow us to develop new services and thus expand our testing capabilities and services for you.

Kiwa's Lab Capabilities

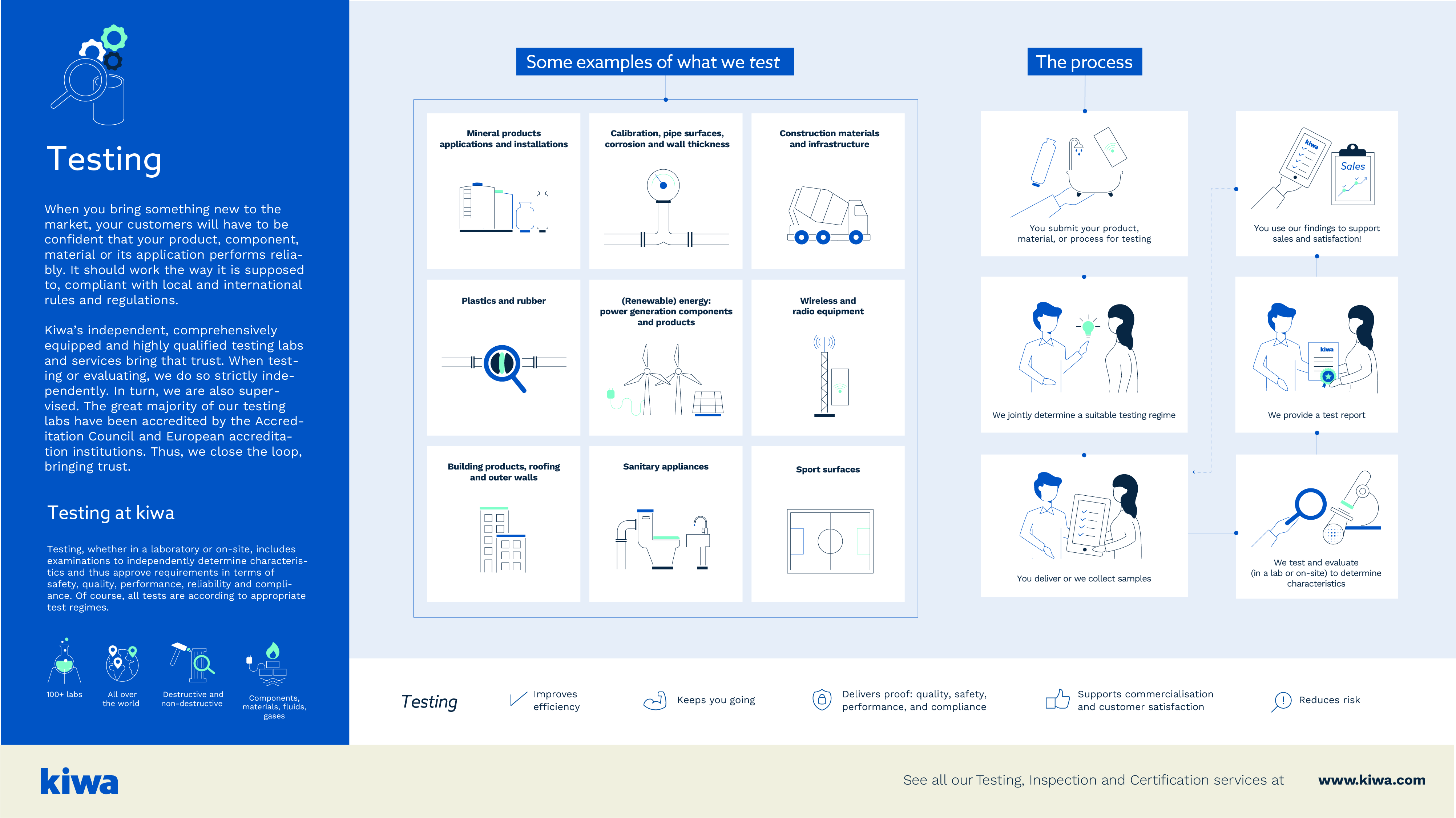

The testing process

You have decided that you want your product, a component or (raw) material to be tested according to a certain regime - perhaps based on certain rules or regulations. (Not sure you want your product to be tested? Here are some reasons to help you decide.) Kiwa helps you by taking samples, performing all necessary tests and providing you with results that make sense.

Product development

Test selection

Delivering samples

Testing process

Results

Pricing

Supervision

Frequently Asked Questions about Testing

Why should I have my product tested or evaluated?

Having your product and/or its application independently tested or evaluated helps to build trust in its proper functioning - both for yourself as a manufacturer or supplier and for customers using it. Here are some more reasons why you should have your product tested.

- Testing proves quality, safety, performance and compliance

Your customer expects nothing less than a product that performs accurately. Having it tested proves it meets requirements regarding quality, safety and performance, and that it complies with all applicable rules and regulations. - Testing reduces risks

A product must do what it is supposed to, and it should function properly for an extended period. Testing your product reduces risks in the form of defects, malfunctioning or accidents in general, as it detects possible errors at an early stage, before harm is done. - Testing keeps you going

A thoroughly tested product will be more reliable, allowing you to keep your organisational (production) processes going without interruptions. - Testing supports commercialisation and customer satisfaction

A recall of a product due to a defect that has gone previously undetected will highlight the value of testing in light of commerce and customer satisfaction immediately becomes clear. Thorough testing regimes help to eliminate defects, thus improving reliability, time to market and commercial success. Your customers will value that. - Testing improves efficiency

For you as a manufacturer, having your product tested and/or evaluated can not only improve the efficiency of your product, but of the entire production process and even your entire organisation as well. By eliminating possible hick-ups in an early stage of development, production will run smoother later on and product quality will be enhanced.

What can Kiwa test for me?

Kiwa can test and evaluate virtually anything for you. Our 100+ labs all over the world have their own (areas of) expertise, but also act as your gateway to our full testing portfolio. Testing capabilities include destructive and non-destructive testing of all kinds of materials, all kinds of electrical and connectivity testing, testing of fluids and gases, their transportation systems and their flow - and many more. Here are just a few examples. Enter a search phrase in the search box to see what we can offer you.

-

Mineral products, applications and installations ranging from production and extraction to distribution, storage facilities and appliances.

-

Construction and infrastructure: materials used in building, civil works and road construction, including mechanical and hydraulic behaviour, durability and environmental aspects.

-

Energy: from components for power generation to energy using products.

-

Polymers or, in other words, plastics and rubbers in a wide variety of markets, from construction products to water and energy distribution and appliances.

-

Roofing and outer walls, including roof and façade coverings composition and stability.

-

Sanitary appliances like taps for drinking water, toilets, pipes, fittings, valves and backflow prevention devices.

-

Sports surfaces, both indoor and outdoor, for practicing all kinds of sports activities.

-

Solar panels, solar heat collectors and installation components.

What is NDT?

NDT stands for Non-Destructive Testing. It means a product is being tested without it being damaged. Examples of NDT are visual testing, ultrasonic testing, radiography testing and leak testing. NDT is opposed to destructive testing, which includes bend, break and impact tests. Combined, they deliver a wealth of information. Kiwa can perform both NDT and destructive testing for you on a wide range of products and materials.

What is calibration?

Accuracy is, of course, the most important factor regarding measurements. Therefore it is important to calibrate and monitor your measurement devices, for example for measuring mass, volume, length, electricity, pressure and heat, on a regular basis. In the calibration process, display readings of the meter are being compared with traceable national and international measurement standards. Kiwa can perform calibrations for all kinds of measuring devices for you.

Contact us

If you have specific questions about testing or if you haven't found what you where looking for, please do not hesitate to contact us.