Why mechanical stress sequence testing matters

Researchers at the Fotovoltaica-UFSC recently designed a 100 kWp site to evaluate bifacial silicon PV module performance under Brazilian climatic conditions. Located in Florianópolis-SC, Brazil, the project uses large-format bifacial glass//glass modules with 2 mm heat-strengthened glass, installed across five single-axis tracking rows and one fixed-tilt system. Little did they know that they would actually be studying module glass breakage.

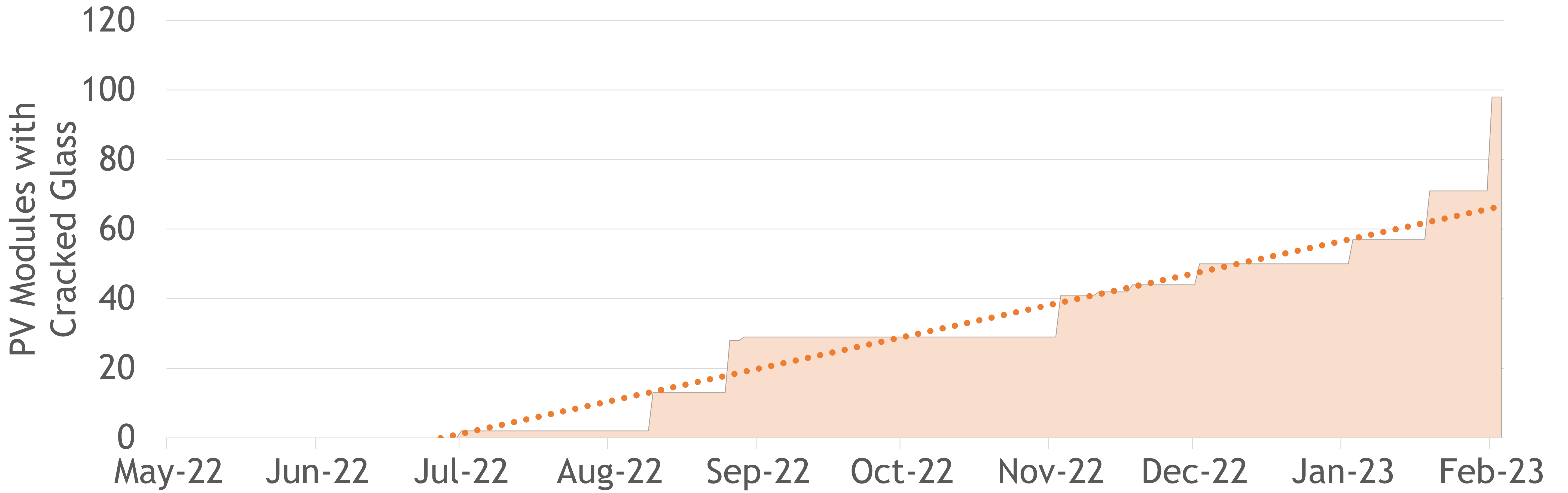

Not long after site commissioning, the researchers noticed glass cracks on the front or rear of some modules. Regular inspections were conducted and a trend of 14 broken modules per month was recorded over a seven-month period. Within nine months of site commissioning, over 50% of the installed modules had cracked glass. The weather monitoring data over this period did not show any temperature or wind event anomalies.

As of early 2023, the glass cracks have not impacted system safety or performance. The researchers have thus far found no correlation between glass cracks and cell cracks on EL images, power degradation, or hot spots. But the long-term reliability of modules with broken glass is certainly at risk. The root cause analysis is still ongoing with the module and racking/tracker manufacturers involved.

This is not a unique case of module breakage in the solar industry. The Kiwa Group members have been contacted multiple times in the past two years with reports of broken glass on PV sites. Tracker/racking compatibility with large-format modules is critical, and Kiwa PVEL’s MSS testing on specific module and tracker/racking combinations provides site stakeholder confidence in avoiding these types of issues.

Fotovoltaica-UFSC case study contributed by: Marília Braga, Gustavo X. A. Pinto, Anelise M. Pires, Alessandro H. Zamboni, Lucas R. Nascimento and Ricardo Rüther at Universidade Federal de Santa Catarina, Florianópolis-SC, Brazil (www.fotovoltaica.ufsc.br)

|

|

| In the majority of cases (59% of all cracked modules) the rear side glass broke. 28% of cracked modules had broken front side glass, and 13% of cracked modules had both front and rear glass broken. | Number of PV modules with cracked glass. The trend line represents ~14 cracked modules per month. |

Materials assessed

These materials influence the mechanical strength of the cell interface as well as the durability and rigidity of the PV module itself:

|

|

Test procedure

|

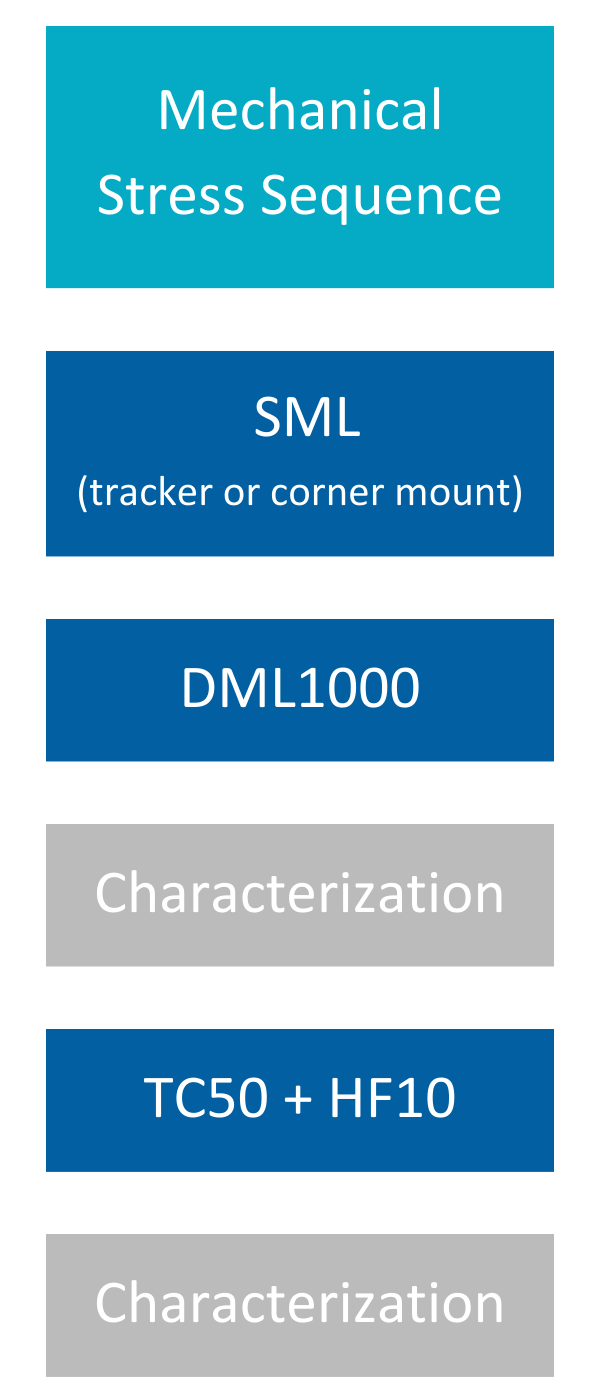

MSS is comprised of four tests in sequence: static mechanical load (SML), dynamic mechanical load (DML), thermal cycling, and humidity freeze. The mechanical loading steps create and propagate cracks in susceptible modules, and then power loss is induced through the environmental stress of thermal cycling and humidity freeze. Historically, the SML included three rounds of one hour of downward force and one hour of upward force at 2,400 Pa with the module mounted using traditional two-rail fixed tilt mounting methods. Starting for all PQPs initiated in November 2023, if the module frame has 400 mm mounting holes, the MSS modules will be mounted using Nextracker’s torque tube and mounting rails, attached to the module using M6 hardware at the module’s 400 mm mounting holes. If the module frame does not have 400 mm mounting holes, the module will be mounted via SnapNRack’s RL Universal Mount, with clamps attached on the short-side frame within 200 mm of the corner. Once mounted, a reduced test load of ±1800 Pa is used for tracker-mount or corner-mount. The subsequent DML test comprises 1,000 cycles of oscillating positive-negative loading at ±1,000 Pa, using the same mounting as SML. After load testing modules are placed in an environmental chamber to undergo 50 thermal cycles (-40°C to +85°C) followed by 10 cycles of humidity freeze (+85°C and 85% relative humidity, then a rapid drop to -40°C). |

|