Hydrogen Embrittlement Testing according to ISO 11114-4 Method A – Disc Method

Receive a quote tailored to your needs

For this purpose metallic materials have to be tested to demonstrate safe use with hydrogen. Kiwa performs hydrogen embrittlement tests according to the ISO 11114-4’s disc method to demonstrate this hydrogen compatibility.

Originally, the ISO 11114-4 was intended as a quality standard for the transport of potentially dangerous substances in gas cylinders. For example, the standard provides guidelines and includes methods for testing the resistance of cylinders to hydrogen embrittlement. Method A, also known as the disc method, is one of the test methods specified in this standard for evaluating the susceptibility of metals to hydrogen embrittlement. The hydrogen and material testing experts of Kiwa have applied the ISO 11114-4 Method A – Disc Method to the testing of the hydrogen compatibility of tanks and components for hydrogen vehicles.

Widely recognized test method

The disc method is widely used and recognized as a reliable test method for evaluating the susceptibility of metals to hydrogen embrittlement. In summary, the disc method is a standard test method used to evaluate the resistance of materials to hydrogen embrittlement. In the disc method, a small, flat disc of the material is placed between two stainless steel flanges. The pressure is increased from one side of the disc with different pressure-rise rates until rupture.

Simulated conditions

The rupture test is carried out with both helium gas and hydrogen gas. The rupture pressures are compared. The ratio between these pressures is an indicator for hydrogen compatibility. The lower the ratio, the less susceptible the steel will be to embrittlement

Why Kiwa?

Kiwa’s alternative fuels and pressure products experts have a lot of expertise in certification and testing for hydrogen applications. We offer service quick responses to client requests and the possibility for a weekly update on testing. We work closely together with Dutch vehicle type approval and registration authority RDW, its German counterpart KBA and Japanese KHK and can also test according to North-American standards.

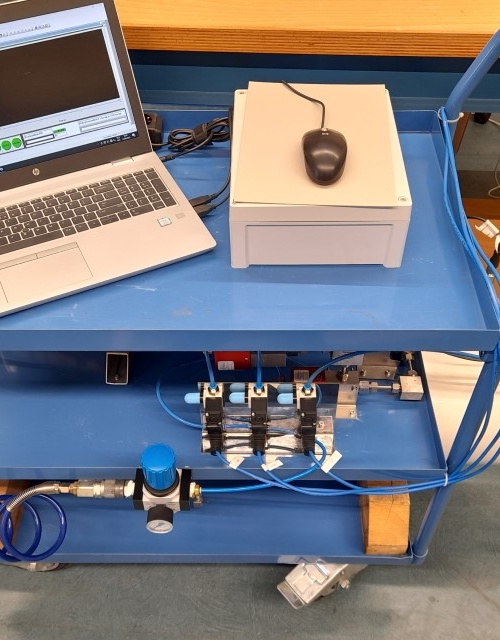

Hydrogen laboratory

Kiwa offers testing and certification services of automotive components for LPG, CNG, LNG and hydrogen sectors, as well as electromagnetic compatibility and several climatic tests. Kiwa is authorized to issue the E4 certification by the Dutch Vehi...

CNG fuel system components testing and certification

Kiwa offers testing and certification services of automotive components for LPG, CNG, LNG and hydrogen sectors, as well as electromagnetic compatibility and several climatic tests. Kiwa is authorized to issue E4 certification by the Dutch Vehicle ...

Testing and certification with alternative fluids such as CNG, LNG, LPG and H2

Kiwa offers manufacturers of components for automotive vehicles using compressed natural gas (CNG) testing and certification services of automotive components for LPG, CNG, LNG and hydrogen sectors, as well as electromagnetic compatibility and several climatic tests.

One-stop shop for manufacturers working in the hydrogen supply chain

Our expert Marijn: “The new hydrogen embrittlement test is a welcome answer to the rapid pace of development and innovation in the field of hydrogen.”Read his full story