Plastic and rubber, testing of physical-mechanical properties

Receive a quote tailored to your needs

You are...

If you are a developer, manufacturer, supplier or user of plastic and rubber products? Then it is good to know that Kiwa carries out all typical tests on plastics and rubber products which are used for gas, heat and water distribution and installation. Tests can be performed on pipes, fittings, seals, the piping system (fitness for purpose) and the resins themselves.

Furthermore, Kiwa can also perform a wide scope of physical and mechanical tests in other sectors, like automotive, industry, infrastructure and construction.

Physical tests

Typical physical (and partly also chemical) tests on polymer materials:

- Melt mass flow rate (MFR);

- Vicat softening temperature (VST);

- Density;

- Degree of crosslinking;

- Thermal stability;

- Permeation of gases (e.g. oxygen, hydrogen, methane, CO2) and liquids;

- Volatile/water content;

- Carbon black/pigment dispersion.

- FTIR spectroscopy (with more than 200,000 reference spectra) and ATR, Diffusion reflection, Pyrolysis-FTIR

- Gas Chromatography

- Extraction and identification of additives

- Determination of resistance against hydrolysis of acetals, nylons, polyesters etc.

- Oxidation induction time (OIT) and other Differential Scanning Calorimetry (DSC)

- Thermal Stability

- Thermo gravimetric analysis (TGA)

- Viscosity and porosity

- Microscopy.

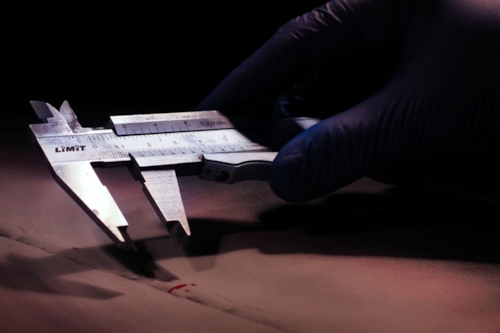

Mechanical tests

Typical mechanical tests on plastics pipes, fittings and other products:

- Resistance to internal hydrostatic pressure;

- Resistance to slow crack growth (SCG, Cone test, PENT, FNCT ,CRB and Strain Hardening Test);

- Resistance to rapid crack propagation (RCP-S4);

- Drop, Impact and Bending testing;

- Tensile impact testing;

- Tensile tests (also at elevated temperatures up to 150 °C;

- Peel decohesion tets;

- Constant-load tests on pipe segments at elevated temperature to determine the residual lifetime of polymers

- Effects of heating.

In short: we can help you with an independent evaluation of the quality of polymeric products.

More information

Please feel free to contact us at rubber@kiwa.nl. You can also read our leaflet for more information first.

Permeation and chemical compatibility

Kiwa is your partner for assessing the chemical compatibility and material performance of applied materials and the corresponding tests like permeation, immersion or rapid gas decompression tests. Testing material samples, pipes, components or even complete systems is possible.

Test equipment for plastics and rubbers

Within the Kiwa organisation there are a large number of accredited laboratories. This means that the scope of possible tests within the entire Kiwa Group is so wide that is impossible to mention them all here. Although not limited to polymer test...

Chemical analysis of polymers and elastomers

Do you have questions about the composition or nature of a polymer material, component, a contamination or a chemical attack? Good to know that Kiwa has a large number of laboratories that are well equipped with a broad variety of different chemic...

Reliability engineering of polymer products

Reliablity engineering of plastic and rubber products. The realisation of reliable polymer and rubber products starts in the design or engineering stage. There the fundamental choices are made that have a major influence on the functioning of the product in the end.