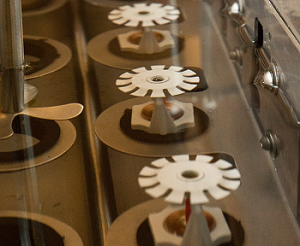

Fixed dry aerosol fire extinguishing components - K23001

Receive a quote tailored to your needs

Stationary dry aerosols fire extinguishing components are designed for use as part of a fire extinguishing system. The fire extinguishing system shall activate these fire extinguishing components.

The fire extinguishing component consists of a container filled with a dry solid extinguishing agent, which after activation is discharged as a dry aerosol to extinguish the fire.

The fire extinguishing component shall be suitable to extinguishing following EN 2 fire classes:

- Extinguishing of class A fires (solids)

- Extinguishing of class B fires (liquids or liquefying substances)

- Extinguishing of class C fires (gases)

- Extinguishing of class F fires (boiling oils and fat fires)

Applicable standards in this certification scheme K23001 are:

- NEN-EN 15276-1 specifies requirements and test methods for condensed aerosol extinguishing system components.

- ISO 15779 Condensed aerosol fire extinguishing systems - Requirements and test methods for components and system design, installation and maintenance - General requirements

Explanation:

Melting plastics are defined as class A fires.

Fires caused by electrical short circuits will lead to class A, B and C fires.

Who for?

Fire detection companies, system administrators.

Process steps

'K23001 Product Certification Scheme for nonpressurized condensed aerosol generators and components used in fixed fire extinguishing systems' outlines performance criteria for system components and requirements for test methods.

In addition, the K23001 outlines requirements for the company’s quality management system. This includes requirements for internal quality control processes, procedures, work instructions and personnel.

Certification process

Certification of your company based on ‘K23001’ starts with an application, after which you receive a fee proposal. You can enter into a certification agreement with Kiwa on the basis of this fee proposal. Kiwa assesses whether the criteria for certification are met based on an independent acceptance audit. Certification will follow upon a positive audit outcome. However, if non-compliances are identified, you shall rectify these first.

Annual inspections are conducted to establish that the certified processes and completes works continue to comply with the applicable requirements in order to maintain your certification based on ‘K23001 Product Certification Scheme for nonpressurized condensed aerosol generators and components used in fixed fire extinguishing systems’ after initial certification.

Why Kiwa Fire Safety & Security?

Kiwa Fire Safety & Security (Kiwa FSS Certification) is a leading certification body for the certification (accreditation) of fire protection and security companies.

Kiwa FSS is an independent Certification Body that determines whether a company meets the quality requirements. A Kiwa FSS Certificate provides the occupant with a well-founded confidence in the quality of the certified company and its services, such as testing, commissioning and maintaining systems.

Certified companies

For certified companies, click here. You could filter on certified scopes.

K23003 Fire Extinguishing Systems based on Dry Aerosol

The K23003 describes the processes with regard to supplying of the basic- and detailed design, installation and the maintenance of fixed fire-extinguishing systems based on condensed dry aerosol for structures and compartments.

K21045 Fire Protection Systems

The K21045 Fire Protection Systems Assessment scheme is a scheme for Testing, Inspecting and Certification (TIC) Fire Protection Systems.

Internal Inspection of Sprinkler System Piping

An automatic sprinkler system must have a reliable pipe system for optimal operation. An internal Inspection of Sprinkler System Piping will give you an insight into the current condition of your sprinkler system.

Remote Access for Remote Services (RARS) Certification Scheme

By taking the recent cybersecurity trends into account, Kiwa developed the Remote Access for Remote Services (RARS) scheme, also known as K21048. The RARS scheme is a collection of assessments set up by Kiwa that focusses on different types of systems that are remotely accessible.

EN-NTA 8133 test Lithium Fire Extinguishers

In order to be sold on the Dutch market, portable fire extinguisher must have the Dutch Approval Mark (Dutch: Rijkstypekeur). Test methods for different fire classes are included in EN 3-7. However, there is currently no designated test method for lithium fire extinguishers in EN 3-7. That is why Kiwa offers lithium fire extinguisher testing according to the Dutch Technical Agreement NTA 8133.

Government Inspection Mark

The Government Inspection Mark is required to be able to sell or trade portable fire extinguishers (up to 20 kg) in the Netherlands. This "quality mark" is indicated in an elliptical symbol printed on the label of a portable fire extinguisher.

Kiwa FSS Testing: test lab for sprinklers

Sprinkler systems have proven to be a reliable fire-protection system for many years. However, many of these systems are showing their age and it is not uncommon to find sprinkler systems that were installed 25 or more years ago. The sprinklers in these systems are dated and will need to be replaced over time as a preventative measure.

Fire Safety Inspection / Inspection Fire Safety By Kiwa

A fire safety inspection (structural fire safety) by Kiwa FSS is conducted based on applicable fire safety regulations, such as the NEN 6059 standard or the VIVB inspection scheme.

Quick scan Fire Safety in Buildings

Kiwa FSS’s quick scan Fire Safety in Buildings is an independent investigation to determine the current status of fire safety precautions.

Inspection PGS 15 Publicatie reeks Gevaarlijke Stoffen (Publication Series on Hazardous Substances)

Guideline 15 from the Publication Series on Hazardous Substances (PGS) contains guidance for the storage of packaged hazardous goods. Kiwa FSS can assess the fire safety aspects in your storage facility during an inspection PGS 15, including from baseline inspection to PGS 15 certification and follow-up inspection.