Sleeve connection assessment for heat distribution networks

Our expertise

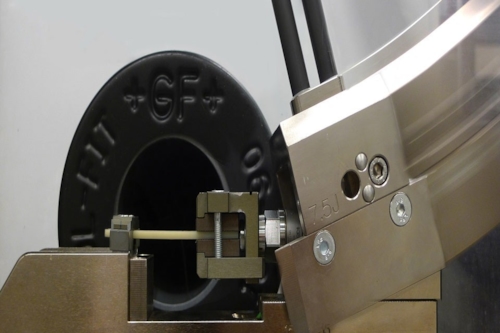

- Laboratory testing: Our modern laboratories perform comprehensive chemical and physical analyses, including leak-tightness tests, adhesion tests of socket connections on PE casing pipes, shear tests and water permeability tests of PUR foam in accordance with EN 253. This helps assess the quality of socket connections and identify potential causes of deficiencies.

- On-site testing: Kiwa Technology also offers the capability to perform leak-tightness tests directly on-site. This enables us to evaluate the quality of socket connections during installation.

Ensure a robust and reliable heat distribution network with the expert support of Kiwa Technology. Improve the quality of your sleeve connections and prevent future issues with our extensive testing and research services.

Go backstage

Take a step inside our technology lab!

Test possibilities materials

At Kiwa Technology, we have years of experience conducting independent damage and material investigations for a wide range of market players, including energy companies, water utilities, contractors, suppliers, manufacturers and insurance companies. Our expertise focuses on pipes and components for energy and water, made from various materials such as copper, steel, plastics and glass fiber-reinforced composites.

Product assessments heat distribution

Do you have a new product in heat distribution, such as a delivery set or heat pump system, or are you in the process of developing one? Ensure your product meets all standards and performs optimally with Kiwa Technology's expertise.

Jointing techniques materials

Problems in pipeline systems often arise at the connections. At Kiwa Technology, we have years of experience investigating and identifying the causes of connection failures. Our expertise in welding plastic pipes (PE, PEX, PA, PP, etc.) and other joining techniques forms the foundation of our high-quality consultancy and research and development projects.

Damage analysis heat distribution networks

Kiwa Technology provides independent damage investigations and targeted advice to prevent future disruptions. Additionally, our modern laboratory allows us to conduct damage analyses through tests and experimental setups.

Tensile impact test plastic according to ASTM D1822 or ISO 8256

Plastic pipes and components are often used for water and other underground infrastructures. Detailed knowledge of the properties of plastics is indispensable to ensure that these materials can perform well for years to come.

Paper

The paper ‘Quality control of joint installation in pre-insulated pipe systems’ was presented during The 14th International Symposium on Heating and Cooling (DHC14).